Manufacturers of Premier Vacuum Heat Treating Furnaces & Specialty Coating Services.

VAC AERO designs and builds vacuum furnace systems and controls with the highest quality standards for any of your specialized processing needs. From small horizontal units to large vertical models VAC AERO vacuum heat treating furnaces are ideal for a broad range of thermal processing applications of engineered materials, and specialty alloys. VAC AERO vacuum furnaces operate worldwide in diverse applications in aerospace, power generation, and other high-tech industries. VAC AERO also offers specialty coating services to the aerospace and high-tech industries including; plasma and High-Velocity Oxy-fuel (HVOF) spray coatings, as well as inorganic paint and pack coatings and other protection applications for wear, erosion, corrosion protection and restoration of both new and service-exposed parts and components of all sizes.

VAC AERO designs and builds vacuum furnace systems and controls with the highest quality standards for any of your specialized processing needs. From small horizontal units to large vertical models VAC AERO vacuum heat treating furnaces are ideal for a broad range of thermal processing applications of engineered materials, and specialty alloys. VAC AERO vacuum furnaces operate worldwide in diverse applications in aerospace, power generation, and other high-tech industries. VAC AERO also offers specialty coating services to the aerospace and high-tech industries including; plasma and High-Velocity Oxy-fuel (HVOF) spray coatings, as well as inorganic paint and pack coatings and other protection applications for wear, erosion, corrosion protection and restoration of both new and service-exposed parts and components of all sizes.

VAC AERO News & Product Information

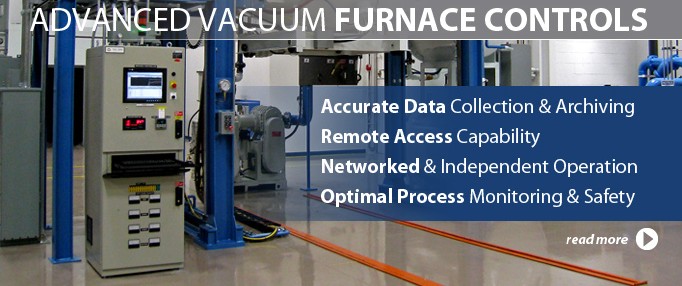

Process Control Upgrades for any Vacuum Furnace Brand

Process Control Upgrades for any Vacuum Furnace Brand

Considering an upgrade to your VAC AERO or any other vacuum furnace control system? The Honeywell HC 900 Hybrid Controller is one of the most powerful control systems on the market today. The HC900 integrates with Honeywell Experion HS software running on a Windows 7-based PC to provide Supervisory Control and Data Acquisition (SCADA). The control system can connect remote users, link multiple furnaces together, or to other operating systems in a facility. It is programmable, logic-based and comprised of proven hardware components, suitably hardened for an “industrial shop” environment.

Vacuum Brazing with Dan Kay

Shell & Tube Heat Exchangers — Methods to Seal Tube-to-Header Joints

Shell & Tube Heat Exchangers — Methods to Seal Tube-to-Header Joints

Brazing has become more and more the desired joining-method to “seal” these heat exchangers from any internal or external leaks. In this article, we look at some of the internal characteristics of S&THE’s, options for sealing them to make them leak-tight, and some important requirements for proper joint design so that brazing can be used to cost-effectively make many tube-to-header leak-tight joints in S&THE’s at the same time!

LATEST ARTICLES Can Brazing Stop-Off Usage be Abused? | Are Recessed Braze-Fillets Okay?

Vacuum Pump Tech: Education & Training

Oil sealed rotary vane pumps (aka rotary vane pumps) are the primary pumps on most vacuum systems used in the heat treatment industry. They are also referred to as a “backing” pump when used in combination with a booster pump, or with both a booster and secondary (“high vacuum”) pump, typically a diffusion style. A rotary vane pump can also be used alone when high vacuum is not required and slower pump-down is acceptable.

LATEST ARTICLES Oil Sealed Rotary Vane Pumps | Proper Selection and Use of Vacuum Gauges | Dry Pumps: Screw Type

Vacuum Heat Treating: Education & Training

A Vacuum Gauge is a pressure measuring instrument that measures pressure in a vacuum (i.e., in a vessel operating at sub-atmospheric pressure). Depending on the type of vacuum system (Fig. 1) and the required operating vacuum level, different vacuum gauges are required, often in combination with one another, to accurately determine and/or control the vacuum level of the chamber at any given moment in time.

LATEST ARTICLES Vacuum Furnace Safety: Information Concerning Confined Spaces

Specialty Coating Services

High-quality coating solutions require a commitment to ongoing investments in state-of-the-art equipment. That commitment has been central to the growth of our coatings operation since 1968. Located in Boucherville, the heart of Quebec’s aerospace community, VAC AERO’s coating division offers specialized surface engineering services to the aerospace and high-tech industries including plasma and high velocity Oxy-fuel (HVOF) spray coatings, as well as inorganic paint and pack coatings and other protection applications for wear, erosion, corrosion protection and restoration of both new and service-exposed parts and components of all sizes.

High-quality coating solutions require a commitment to ongoing investments in state-of-the-art equipment. That commitment has been central to the growth of our coatings operation since 1968. Located in Boucherville, the heart of Quebec’s aerospace community, VAC AERO’s coating division offers specialized surface engineering services to the aerospace and high-tech industries including plasma and high velocity Oxy-fuel (HVOF) spray coatings, as well as inorganic paint and pack coatings and other protection applications for wear, erosion, corrosion protection and restoration of both new and service-exposed parts and components of all sizes.

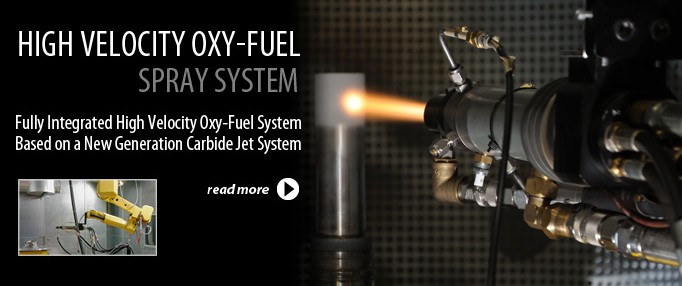

High-Velocity Oxygen Fuel (HVOF) Coatings

VAC AERO’s Boucherville, Quebec-based Coatings facility operates a fully integrated state-of-the-art High-Velocity Oxygen Fuel (HVOF) system based on a new generation carbide jet system. This process is ideal for the protection and restoration of both new and service-exposed components primarily in the aerospace and power turbines industries. Services include a variety of protective coatings for gas turbine engine and airframe components, hot section thermal barrier coatings for combustion and afterburner liners, and abradable seal coatings in high and low-compressor casings.

VAC AERO’s Boucherville, Quebec-based Coatings facility operates a fully integrated state-of-the-art High-Velocity Oxygen Fuel (HVOF) system based on a new generation carbide jet system. This process is ideal for the protection and restoration of both new and service-exposed components primarily in the aerospace and power turbines industries. Services include a variety of protective coatings for gas turbine engine and airframe components, hot section thermal barrier coatings for combustion and afterburner liners, and abradable seal coatings in high and low-compressor casings.

Vacuum Gauges

Vacuum Gauges