Large heat-treating facilities are substantial electricity consumers. Specializing in vacuum heat treating and brazing for aerospace and other high-technology industries, VAC AERO International’s Oakville, Ontario, plant operates more than 24 vacuum, air and controlled-atmosphere furnaces. Included are three very large vacuum oil-quench furnaces, all of which result in substantial electricity consumption. Indeed, the company’s electricity costs have increased by more than 30% in recent years, thereby driving an effort to find lower-cost solutions.

As North American electricity rates continue to rise, consumers are looking to new tech-nologies to control their energy usage and reduce costs. Heat-treating operations using electrically heated furnaces are especially vulnerable due to their high level of consumption and difficulty in passing on cost increases to their customers.

One component of electricity’s cost is the amount used. Savings can be achieved by improving energy efficiency, which reduces the amount of electricity consumed. But savings can also be easily achieved by making slight changes to the timing of this consumption, thereby reducing the peak electricity demand.

Utilities need to be able to supply the highest instantaneous demand from their customers. This peak generating capacity is expensive to build and maintain, not always environmentally friendly and underutilized much of the time. As a result, utilities calculate a customer’s bill based not only on consumption but also on peak demand. This may appear as a line item or be hidden within a “delivery” charge. In most jurisdictions, the peak demand is calculated as the highest average demand in any 15-minute time span during the billing period. Since a significant portion of a plant’s electrical energy costs is determined by its peak demand, efforts to lower the peak can result in worthwhile and ongoing savings.

Electricity costs in Europe are much higher than in North America. This environment has created an eager European market for energy-optimization systems that can control and limit peak demand. VAC AERO has recently completed the installation and start up of an energy-optimization system at its Oakville heat-treating facility. The system was provided by dibalog North America Inc., a division of dibalog GmbH of Heidelberg, Germany.

Energy Optimization – How it Works

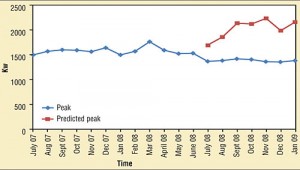

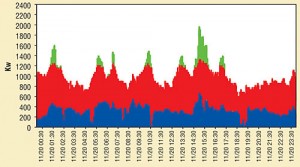

Each electrical consumer (furnace) is equipped with a small field module (Fig. 1). This module continuously monitors the consumer’s power usage and feeds the information back to a central controller. The central controller (Fig. 2) analyzes this real-time demand data together with each consumer’s recent demand history. This analysis yields a prediction of the coming total electrical demand or peak. If the controller predicts that this peak will exceed a programmed value, it takes actions to reduce demand and keep the peak below this limit (Fig. 3).

The energy-optimization system limits peak demand by making small, short-term reductions to the power consumption of individual furnaces. It does so intelligently, by preferentially regulating power to those furnaces that will be least affected. It also distributes the reductions among as many furnaces as possible, for as brief a time as possible. It considers how much power each furnace can spare and under what conditions a furnace’s power should never be reduced (Fig. 4).

Each consumer’s power is reduced for only a short duration, with consumers taking the reduction in turns. Adding more consumers to the system, whether large or small, allows for the load shedding to be shared more broadly. The reductions are small enough in size and duration as to be insignificant in comparison to the furnace and workload’s thermal mass. Consumers with variable power supplies experience a brief reduction in power output. Consumers with on-off power supplies experience a slight decrease in “on” time. Additionally, on-off cycles are phased so as to balance the power demand. The intelligence programmed into the energy-optimization system ensures that furnaces and loads are not detrimentally affected and cycle times are not significantly increased. Each consumer is individually configured in the central controller, ensuring that the regulation is optimized for the characteristics of that consumer.

Installation and Configuration

The energy-optimization system is comprised of a single central controller and field modules installed in the individual consumers. The field modules intercept the command signal from the furnace’s control system before it reaches the device that controls the furnace’s heating-system power supply. The modules monitor the furnace’s power demand and transmit this information back to the central controller. A majority of the time the modules pass along the command signal unaltered to the heating system’s power supply. If the central controller determines that action is required to prevent the peak demand from exceeding the programmed limit, however, it will instruct the modules to briefly override the command signal.

The modules are connected to the central controller through a shielded bus network cable. Multiple furnaces can be connected in series, with a single cable running back to the central controller. Installation of the modules is quick and simple, requiring only about one hour of downtime per furnace to wire and test the modules. The central controller is connected to a standard PC that logs all recorded data and system actions. The computer also provides a graphical interface to configure and monitor the system. Aggregate demand can be viewed on a five-minute basis, either as a bar graph or actual values. Regulation of individual furnaces can be viewed on a minute-by-minute basis.

Once the installation was complete, the system was left in a monitoring mode for approximately six weeks. During this time, the central controller monitored and recorded the energy requirements of all the consumers. This data provided dibalog’s engineers with the usage patterns and heating characteristics of each furnace. Drawing on their extensive experience, the engineers configured the regulation actions for each furnace and determined an initial peak limit. A conservative limit was initially selected. This reduced the chances of negatively affecting the furnaces and allowed the engineers to continue to refine the system configuration. Over the next weeks, the limit was gradually lowered. Close communication between VAC AERO and diablog ensured that maximum savings were achieved while maintaining product quality and cycle times. Dibalog was able to monitor and configure the system using a secure VPN channel across the Internet.

Results

The energy-optimization system began regulating VAC AERO’s peak electrical demand in July 2008. The monthly savings have increased over time as the peak limit has been lowered. The system is currently keeping peak demand approximately 30% lower than it would be without energy optimization (Fig. 3).

Savings are expected to increase further over the coming years due to several factors. VAC AERO’s production is increasing, resulting in more cycles running concurrently. Without the energy-optimization system, this would rapidly increase the peak demand and resulting charges. The scheduled addition of a new large vacuum oil-quench furnace in the fourth quarter of 2009 will further increase potential savings. Lastly, as the cost of peak power continues to rise, it increases the savings achieved by the energy-optimization system.Current projections will see the system paid for in less than two years. VAC AERO was able to apply for and receive a rebate through its local utility’s Electricity Retrofit Incentive Program. When this rebate is considered, payback is reduced to approximately 12 months.

In addition to providing heat-treating services, VAC AERO manufactures vacuum heat-treating furnaces for the global market (Fig. 5). Based on VAC AERO’s own experience with energy optimization, the company is now in a position to provide advice to its furnace customers on the potential benefits of energy-optimization systems.In 2009, an upgrade is planned to the newest generation of central controller, which incorporates web-based visualization and setup combined with an encrypted Nadcap-conforming database and additional internal storage. As a result of this upgrade, a dedicated PC will no longer be required for configuration, visualization and data logging. Dibalog makes software updates available two to three times a year at no charge.

Mark Passalent – VAC AERO International Inc., Oakville, Ontario, CANADA