VAC AERO International is a global leader in Furnace Manufacturing, Vacuum Processing and Coating technologies. With five plants in Ontario and Quebec, Canada, VAC AERO’s global high-response service and support teams are always on call to provide direct assistance and expert advice to our clients around the world. CANADA, Ontario VAC AERO’s Head Office is […]

Archives for August 2015

Resources

Coatings

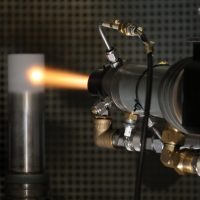

Specialty coating services to the aerospace and high-tech industries include; plasma and high-velocity Oxy-fuel (HVOF) spray coatings as well as inorganic paint and pack coatings. VAC AERO’s Coatings plant is located in the heart of Montreal, Quebec aerospace community. VAC AERO’s Coating Division specializes in plasma and flame-coating services for wear, erosion, corrosion, and thermal […]

Vacuum Furnaces: Horizontal (front-loading) & Vertical (bottom-loading)

Premier Manufacturers of Advanced External Quench Vacuum Furnaces for Superior Processing. VAC AERO is committed to building vacuum furnaces with the lowest cost of ownership achieved through superior design, top quality materials, and high-performance operation. READ HUNDREDS OF TECHNICAL THERMAL PROCESSING PAPERS & ARTICLES HORIZONTAL & VERTICAL VACUUM FURNACE SPECIFICATIONS (SEE BELOW) VAC AERO designs […]

Using the Control Chart Approach to Evaluate Hardness Tester Performance

The control chart data analysis approach is an ideal method to evaluate the quality of test data using a specific tester, such as a microindentation hardness tester, over a period of usage time. The method described in ASTM E2554 was used for this work. This analysis is done by plotting a means and a standard deviation control chart of the weekly/periodic verification data obtained with certified hardness test blocks at a specific test force and a specific hardness level. The method is illustrated using a Knoop hardness test block certified at a test force of 500 gf and with a long diagonal length of 116.18 μm (527.1 HK). From this data, one can easily calculate the uncertainty of the measurements.

The control chart data analysis approach is an ideal method to evaluate the quality of test data using a specific tester, such as a microindentation hardness tester, over a period of usage time. The method described in ASTM E2554 was used for this work. This analysis is done by plotting a means and a standard deviation control chart of the weekly/periodic verification data obtained with certified hardness test blocks at a specific test force and a specific hardness level. The method is illustrated using a Knoop hardness test block certified at a test force of 500 gf and with a long diagonal length of 116.18 μm (527.1 HK). From this data, one can easily calculate the uncertainty of the measurements.

The Control Chart method described in ASTM E2554, and discussed by Neil Ullman, is an ideal procedure for evaluating the performance of hardness testers as it will detect any abnormalities that may occur with usage time. The control chart concept was first developed by Walter Shewhart in 1931 to define the state of statistical control and to detect random or special problems. In 1933, ASTM Committee E1 produced STP 15, “ASTM Manual on Presentation of Data.” This was supplemented in 1935 with “Presentation ± Limits of Uncertainty of an Observed Average,” the first use of the term “uncertainty” in statistical analysis of test data. Today, additional information on control charts is provided by E2587.

Image caption: Microstructure of wrought 7-Mo Plus duplex stainless steel (Fe – <0.03% C – 27.5% Cr – 4.2% Ni – 1.75% Mo – 0.25% N) electrolytically etched with aqueous 20% NaOH (3 V dc, 5 s) to color the ferrite blue. There is some light yellow-tan coloring of the austenite. The average Knoop hardness of the austenite was 361.8 HK and that of the ferrite was 263.5 HK. Magnification bar is 20 µm in length. 7-Mo Plus is a registered trademark of Carpenter Technology Corp., Reading, Pennsylvania.

Vacuum Deposition Processes

Vacuum deposition is a generic term used to describe a type of surface engineering treatment used to deposit layers of material onto a substrate. The types of coatings include metals (e.g., cadmium, chromium, copper, nickel, titanium) and nonmetals (e.g., ceramic matrix composites of carbon/carbon, carbon/silicon carbide, etc.), deposited in thin layers (i.e. atom by atom or molecule by molecule) on the surface.

Vapor deposition technologies include processes that put materials into a vapor state via condensation, chemical reaction, or conversion. When the vapor phase is produced by condensation from a liquid or solid source, the process is called physical vapor deposition (PVD). When produced from a chemical reaction, the process is known as chemical vapor deposition (CVD). These processes are typically conducted in a vacuum environment with or without the use of plasma (i.e., ionized gas from which particles can be extracted), which adds kinetic energy to the surface (rather than thermal energy) and allows for reduced processing temperature.

VAC AERO Launches a New Vacuum Pump Technology Column with Dan Herring in collaboration with Edwards Vacuum!

This is the first in a new series of articles to be entitled “Practical Vacuum Pump Practice with Dan Herring.” Burlington, Ontario, February 16, 2015 – VAC A new column, written by vacuum heat treating expert Dan Herring “The Heat Treat Doctor”® in collaboration with Edwards Vacuum will be published monthly and offer helpful tips and techniques […]